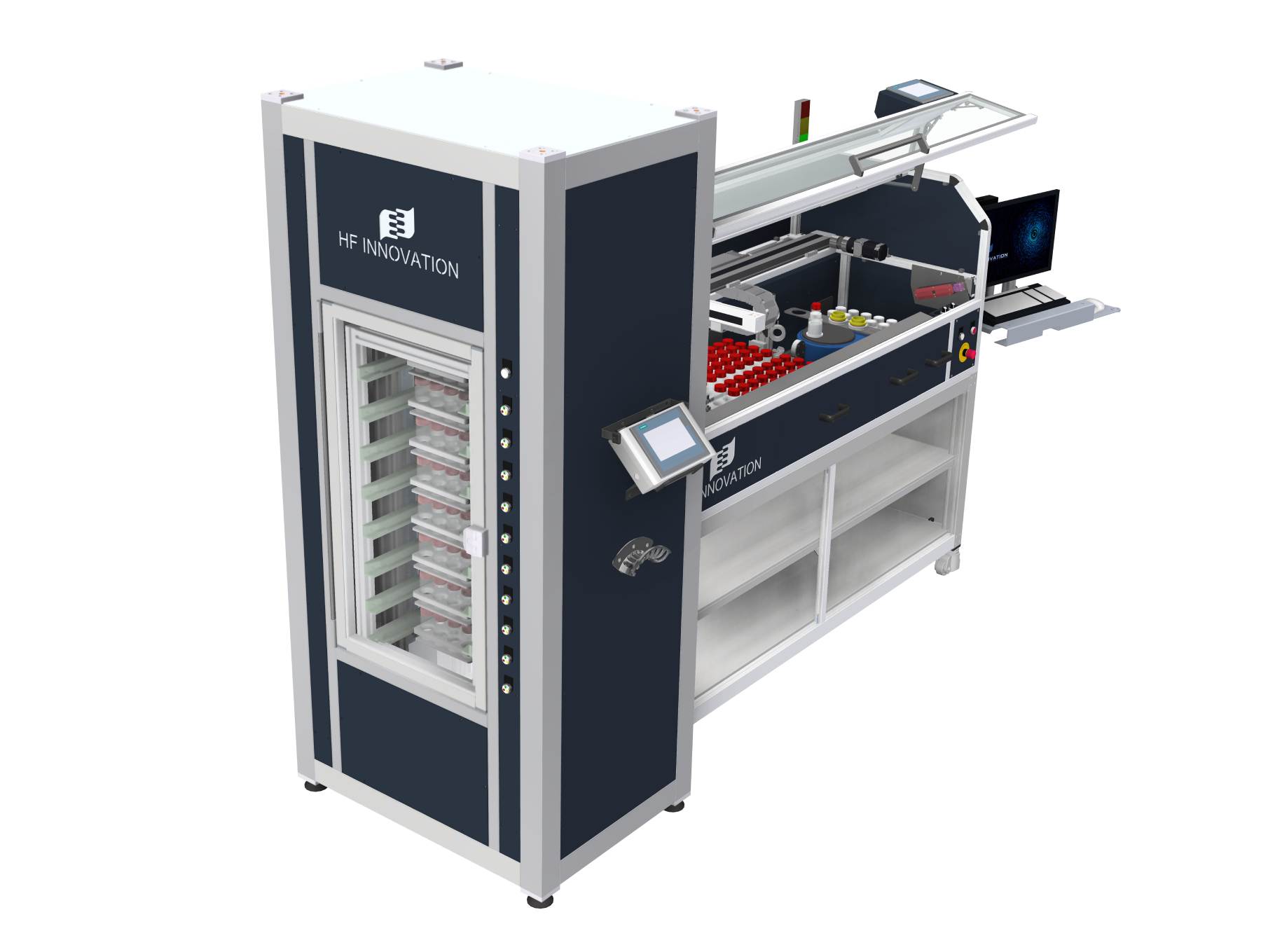

Bringing Industrial Automation to Your Laboratory!

HF Automated Lightning PQ is an automated solution based on the ANALEXPQ that processes high sample volumes, with accurate measuring of ferrous wear debris, irrespective of particle size and distribution. The automation can include optional Camera systems for photographing the sample bottle and debris located on the base of the bottle. Additionally, systems to measure Turbidity and Colour are available.

The lightning PQ is one of the fastest automated systems available for measuring the PQ index across a wide range of sample types. It features an industrial high-speed XYZ cartesian robot and can analyse up to four samples per minute, which equates to over 5700 samples per day.

A wide variety of bottle types can be catered for, as well as their orientation. The system will automatically detect the bottle type and orientation, and then select the appropriate adaptor.

System calibration is automated and by integrating with LIMS automated, re-runs can be set for samples measuring outside of expected values. Some of our customers have analysed more than 3 million samples on these robust systems.

- 15-20 second cycle time from analysis to analysis for samples.

- Multiple bottle/container types and orientations can be analysed at the same

time in the Lightning PQ. - It can also run the QA/QC samples before each rack, verifying the results are within the specification.

- Perform an automatic calibration with the included 0 and 750 PQ standards before or after running a new batch of samples and report these values to LIMS.

- Two integrated cameras take high resolution pictures of the side and bottom of each sample bottle, allowing the interpreters and customer to see the physical appearance of each sample.

- An optional system to measure turbidity and colour is available for this machine.

- A vertical tray magazine is available to increase the unattended runtime of the machine. This magazine can hold an additional 10 trays of samples.

- The ANALEXPQ machine can be used manually in the case of maintenance/emergencies.

- The entire system can be connected to the HF fully automated future lab system.

- Ultra-Fast Analysis

The industrial High-speed XYZ cartesian robot analyses up to four samples per minute, processing over 5,700 samples daily. - Versatile Bottle Handling

Supports various bottle types and orientations with automatic detection and adaptor selection. - Rapid Cycle Time

Achieves 15-20 second cycle times for faster throughput. - Simultaneous Multi-Bottle Analysis

Handles multiple bottle/container types and orientations in a single run. - Integrated Calibration

Automatically calibrates with 0/750 PQ standards and runs calibration discs, ensuring accuracy and LIMS reporting. - High-Resolution Imaging (Option)

Dual cameras capture detailed images of sample bottles for enhanced interpretation and record-keeping. - Automated Colour Analysis (Option)

Performs colour evaluations from photos, guiding further lab testing decisions. - Automated Turbidity Measurement (Option)

Measure the turbidity of the sample guiding further lab decisions. - Manual Operation Mode

Enables manual use during maintenance or emergencies for uninterrupted operations. - Lightweight, Priority Trays

It prevents misalignment and includes a priority tray for urgent sample analysis. - Accommodates Different Tray Sizes

The machine is built to accommodate your standard trays. - Tray Vertical Magazine (Option)

An additional magazine is available that will accommodate up to 10 additional trays. This ensures a longer unattended run time. - Industry-Standard Compatibility

Integrates seamlessly with PQ analysers like Parker ANALEXpql for dependable results. - User-Friendly Interface

Features a built-in touchscreen and PC access via HF’s AVANTICA software on a server-based VM. - LIMS Integration

Offers compatibility with popular LIMS platforms, exporting results in customisable formats like CSV, XLS, and TXT. - Enhanced Safety

Mechanically interlocked doors ensure safe operation at all times. - Modular and Customisable Design

Supports additional analytical methods, including FTIR, viscometry, and turbidity analysis. - Future-Ready Scalability

Expandable to integrate with HF’s full range of laboratory automation solutions.

- Modular Design

Compatible with a variety of laboratory equipment and adaptable for flexible use. - Multi-Sample Versatility

Simultaneously analyses multiple bottle types and orientations, enhancing efficiency and flexibility. - Automated Calibration

Self-calibrates using 750 and 0 PQ calibration discs, verifying results for every rack to ensure accuracy. - Threshold Monitoring

Highlights samples exceeding thresholds, prompting cleaning and reanalysis. Alerts can be sent via alarm or email if limits are exceeded again. - Manual Operation Mode

Allows manual use during maintenance or emergencies, ensuring continuous operation when needed.

- Clinical Laboratories

For sorting blood, urine, and other body fluid samples for diagnostic testing. - Pharmaceuticals

Used in drug discovery, quality control, and pharmacokinetics for sample organization and handling. - Biotechnology

For sorting samples in genetic research, DNA sequencing, and other molecular biology applications. - Forensic Laboratories

In crime labs to handle and organize biological samples for DNA analysis and toxicology. - Environmental Testing

Sorting soil, water, and air samples for contamination analysis and environmental monitoring. - Food and Beverage Industry

In quality control labs for sorting samples to test for contamination, additives, and nutritional content. - Agriculture and Plant Research

Used for sorting plant or soil samples in crop research, soil analysis, and agricultural studies. - Chemical Industry

Sorting samples for quality control, research, and chemical synthesis processes. - Veterinary Laboratories

For sorting samples from animals for diagnostic and research purposes. - Academic and Research Institutions

In university and research labs for organising various biological, chemical, and environmental samples. - Public Health and Epidemiology

For sorting large volumes of samples during disease outbreaks for surveillance and epidemiological studies.

- Toxicology

Sorting samples in toxicological studies for poison and drug testing. - Cosmetic Industry

Sorting samples in research and quality testing of cosmetic products and ingredients. - Industrial Manufacturing

In labs that test materials and compounds to ensure quality and compliance with regulatory standards. - Military and Defense

Sorting samples for biological or chemical analysis in defense-related research. - Oil Condition Monitoring Laboratories

Sorting oil samples to monitor machinery wear, contaminants, and oil degradation in industries like automotive, aerospace, and heavy machinery. - Coolant Condition Monitoring Laboratories

Used to sort coolant samples to check for contamination, pH levels, and overall coolant quality, often in automotive and industrial applications.

Feature | Details |

Sample analysis time | 15-20 seconds (including 4 seconds for PQ analysis. Optional camera adds another 2-3 seconds) |

Daily throughput | ~5700 samples per 24h |

Sample capabity | Typically 2 x 32 position trays or 1 x 50 position tray (can be modified upon request) |

Dimensions | 1600mm (L) x 870mm (W) x 935mm (H) |

Mass | ~220kg |

Electrical requirements | ~2.5 kVA at 230 V, 1 Φ, 50/60 Hz(can be modified upon request) |

Interface | Ethernet |

Accessories | Computer and monitor |

HF’s robust Automated Lightning PQ is engineered for exceptional speed and efficiency, analysing up to four samples per minute and over 5,700 samples daily. Its industrial high-speed XYZ cartesian robot ensures a swift 15-20 second cycle time per sample, ideal for high-volume labs. The system automatically detects and adjusts to various bottle types and orientations, providing seamless adaptability for diverse sample requirements.

Accuracy is a priority with the Lightning PQ. It features automated calibration using 0 and 750 PQ standards, alongside calibration discs for every rack, ensuring reliable results. Integration with industry-standard analysers and LIMS platforms streamlines data reporting. Advanced features like threshold monitoring with automated re-runs of samples if required, high-resolution imaging, and automated alerts further enhance precision and decision-making.

User-friendly and safe, the Lightning PQ includes lightweight trays to prevent mix-ups and hot-swappable drawers for uninterrupted operation. Its ergonomic design, intuitive touchscreen interface, and modular construction allow customization for additional methods like FTIR or viscometry, making it a scalable solution for future lab automation needs.

Ready to bring industrial-grade automation into your lab? Contact us today to discover how HF’s Decapper Aliquoter & Analysis Module can elevate your sample processing capabilities.

- Product Brochure Download

- Case Studies

- Request a Demo