A gold mining customer in Canada was preparing and processing samples for analysis manually, which was time-consuming, repetitive, and hazardous (e.g., hot objects and strong acids). Their goal was to combine all these steps into a single automated system, eliminating the operator’s exposure to the hazards and allowing them to perform other more valuable and safer tasks within the laboratory.

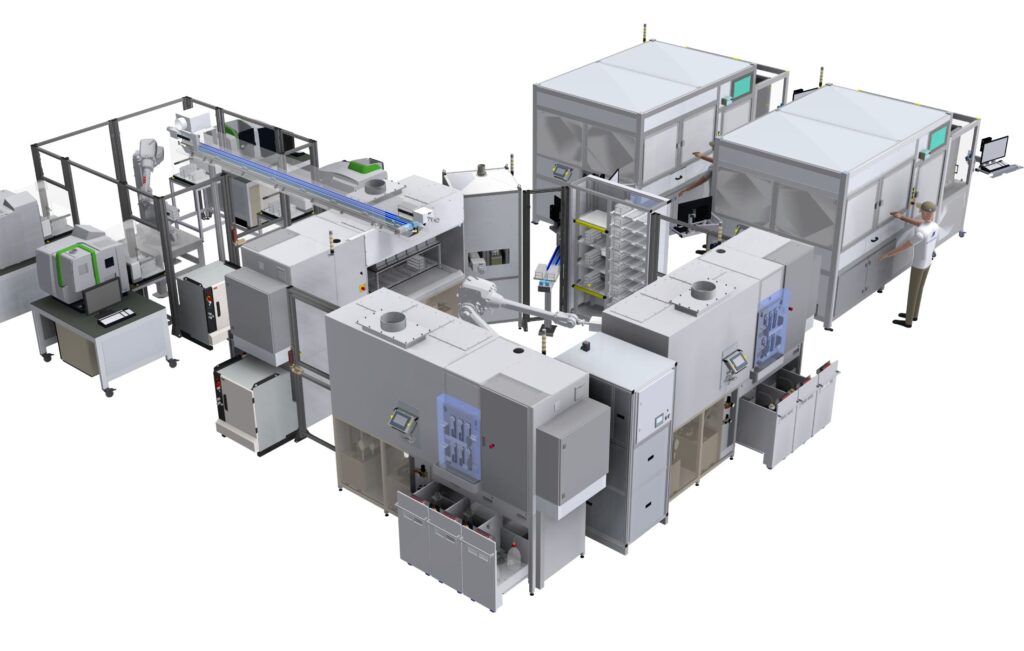

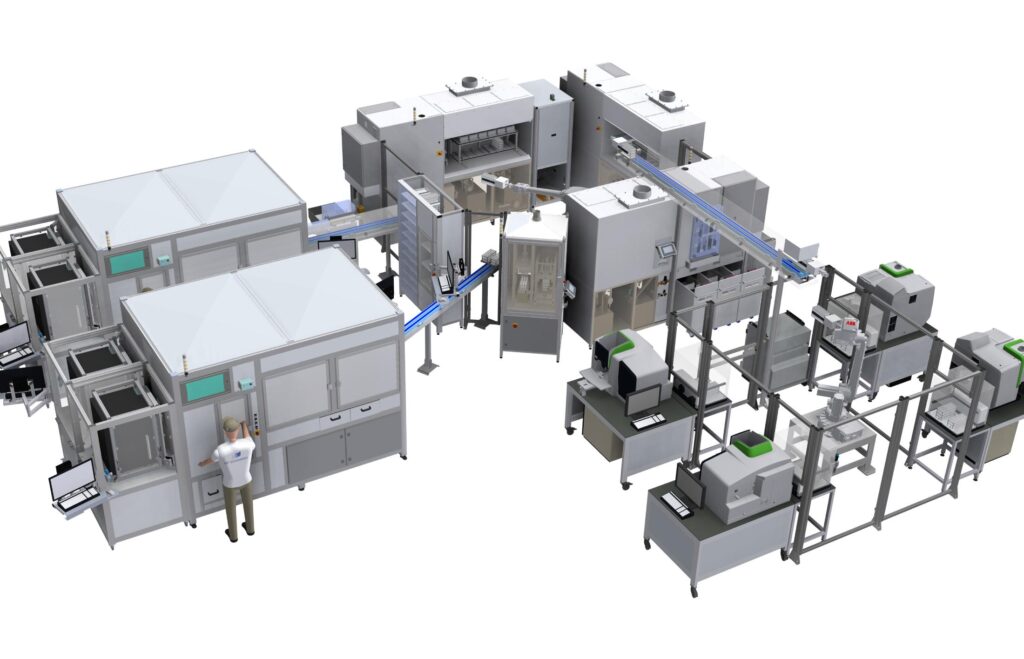

Sample processing also needed to be faster and more efficient due to the high number of samples. The customer approached us for a solution to their challenges. HF, with its impressive and diverse portfolio of automated systems, has succeeded in developing a highly innovative system that can effectively prepare and analyse samples by integrating and automating the customers‘ instruments of choice.

By leveraging our extensive experience in developing automated systems, HF has been able to create a solution that is both reliable and efficient, ensuring that its customers can perform their tasks with the utmost precision and accuracy.

The system can automatically prepare and analyse over 1600 samples per day for carbon sulphur (CS) analysis and perform automated aqua regia digestions for inductively coupled plasma (ICP) spectroscopy and atomic absorption spectroscopy (AAS) analysis.