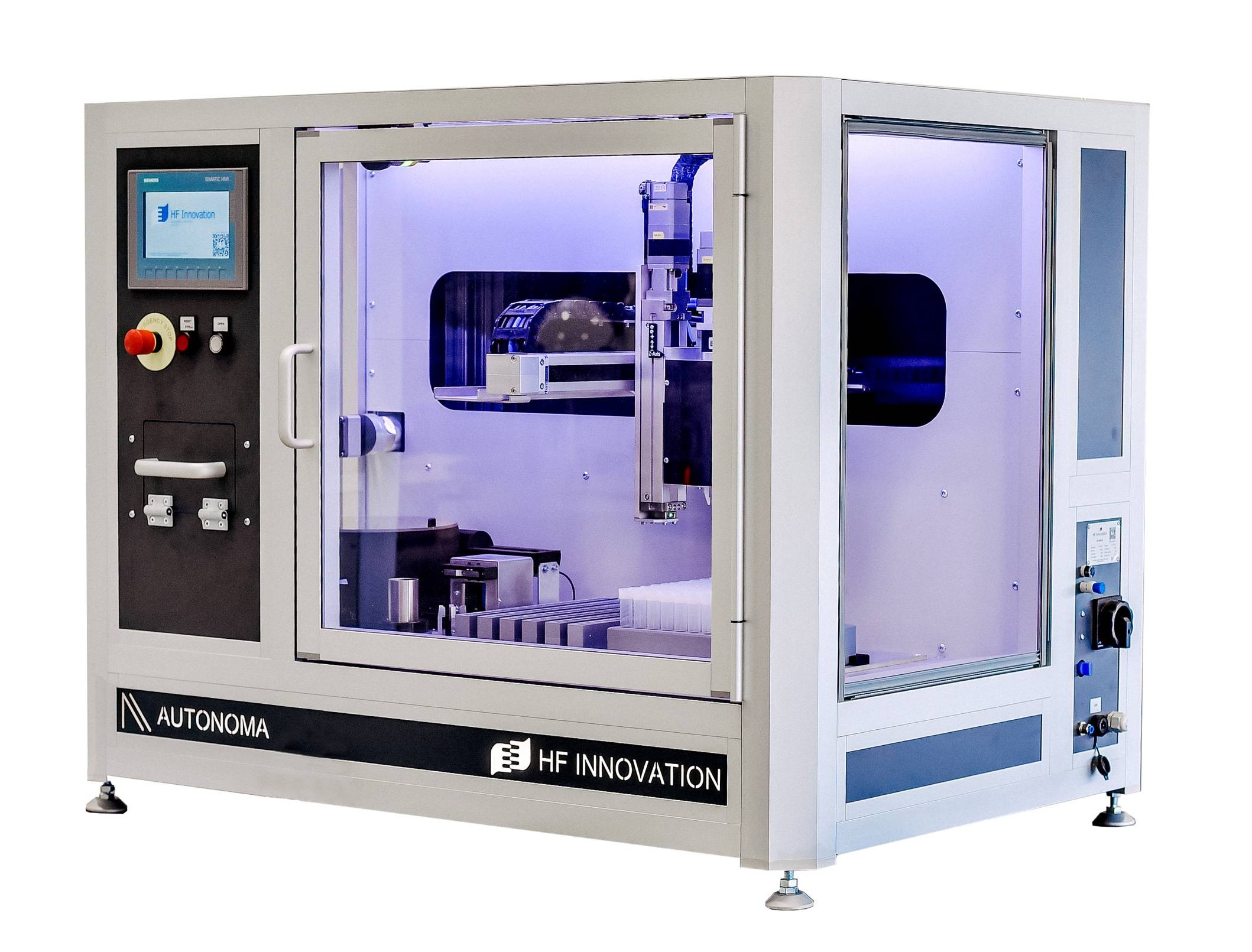

Ensuring the integrity and traceability of forensic urine samples is a critical requirement in law enforcement and forensic laboratories. HF Innovation has developed an advanced automation solution that streamlines the handling of these samples, eliminating manual inefficiencies while maintaining the highest standards of security and compliance.

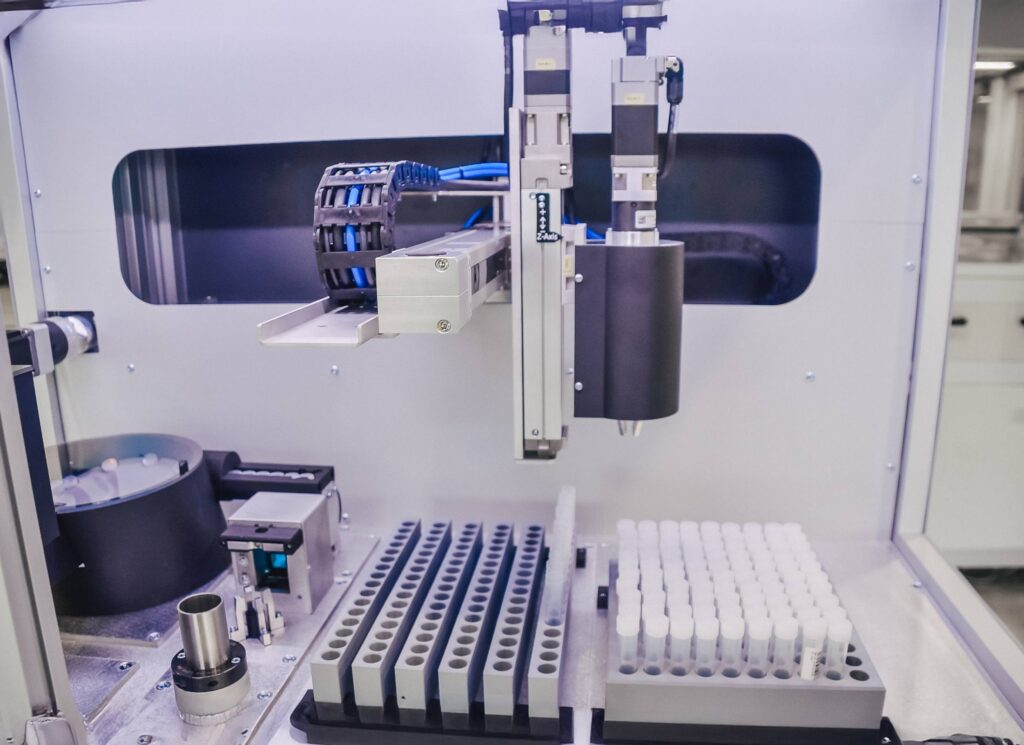

This automated system begins by identifying each sample through barcode recognition, ensuring complete traceability. The automation then performs a precise, automated cutting of the sample seals, guaranteeing that the samples remain tamper-proof throughout the process. Once the seals are removed, the system discards the lids and systematically transfers the tubes into racks, preparing them for analysis.

After the analytical procedures are completed, the automation returns the processed samples to their designated racks and securely applies fresh lids to each tube, ensuring they are properly archived for future reference.

Automated Sample Preparation – Less Strain, More Safety

In high-throughput laboratories, precision and efficiency are crucial. Manually opening and recapping test tubes not only places a significant physical strain on staff but also increases the risk of mix-ups and contamination. The HF-ADCM (Auto Decapper Capper Module) provides a fully automated solution that simplifies test tube handling, minimizes errors, and reduces workload.

Why automate?

- Reduces strain on staff – Eliminates repetitive, physically demanding tasks.

- Ensures maximum safety – No direct contact with sample contents.

- Prevents mix-ups – Barcode scanning ensures each test tube is correctly identified upon insertion.

- Fast and efficient – Processes up to 180 test tubes per hour (3 per minute).

- Highly flexible – Supports multiple test tube sizes and magazine configurations

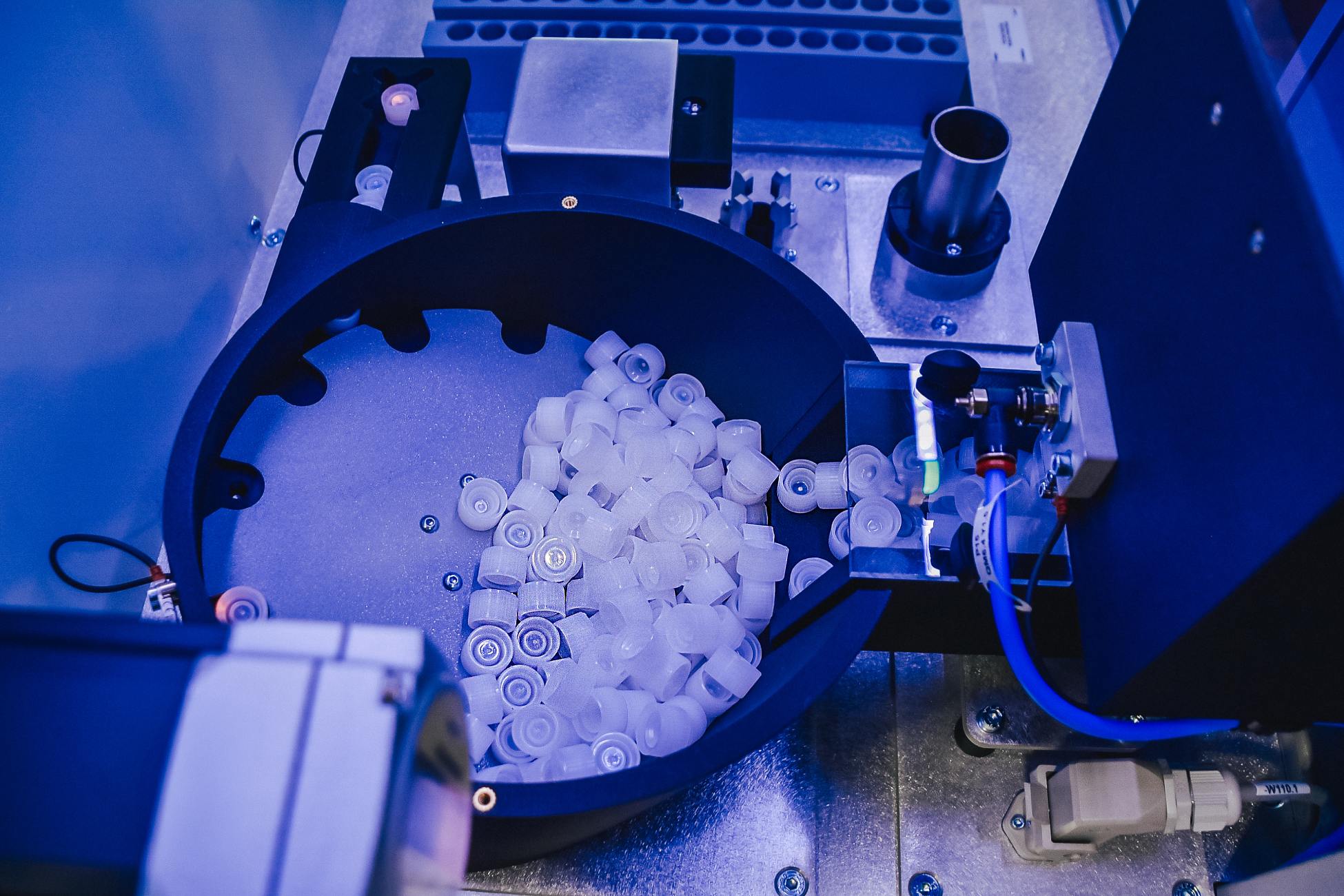

- Easy maintenance – External cap disposal for quick and hygienic exchange.

- Seamless integration – Works within existing workflows or fully automated systems.

How the HF-ADCM works:

- Test tubes are placed → Barcode scanner automatically identifies each test tube.

- Seal is cut and cap removed → Cap disposal via an external waste system.

- Test tubes are transferred for analysis.

- After analysis: Test tubes are reinserted and automatically recapped with new caps.

Performance at a glance:

- Processing speed: 3 test tubes per minute | 180 test tubes per hour.

- Batch time (96 test tubes): Approximately 32 minutes.

By automating sample preparation, laboratories reduce physical strain on staff while enhancing reproducibility, security, and efficiency in their workflows.

HF Innovation continues to lead the way in intelligent automation, setting new benchmarks for precision, reliability, and compliance in forensic and clinical laboratories.

Join the HF Robo Revolution and experience the future of laboratory automation!